Product List

Gravity Casting

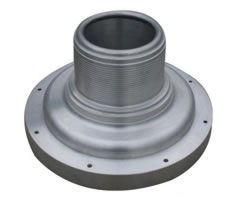

Description

The gravity casting is one type of permanent mold casting, which has advantages of reusable mold, good surface finish, excellent dimensional accuracy and high production rates. The common metal casting material composes aluminum, aluminum alloy, and brass. Material selection is according to technical standards, including ASTM, ANSI, SAE, DIN and BS.

Features

1. Typical parts made by gravity casting includes machine components, various housings, motors, instrument enclosures, etc.

2. The brass gravity cast products are mainly used in fluid control system, such as brass valves, couplings and adapters.

3. Brass cast parts have a wide application in mine industry, oil field, fire fighting field, fluid pressure transmission parts, etc.

4. Besides brass valves, we also produce house decoration parts, brass cast kitchen parts and brass cast furniture parts.

Permanent Mold Casting Processes

Aluminum Gravity Casting

Advantage:

1. Its casting parts have excellent mechanical properties compared with that of die casting parts.

2. Because aluminum gravity cast parts has very lower porosity than aluminum die casting parts.

3. Be generally sound, provided that the casting aluminum alloys used exhibit good fluidity and resistance to hot tearing.

4. Mechanical properties of permanent mold castings can be further improved by heat treatment.

Brass Gravity Casting

Advantage: Brass gravity cast products have a much superior surface quality than that of brass sand cast products.

We are a professional supplier of gravity casting in China, offering a high quality affordable permanent mold casting solution. We also provide the following services:

1. Heat Treatment: Hardening, Annealing, Normalizing, Stress Relieving, Softening, and Graphitization.

2. Machining:Turning, Boring, Drilling, Milling, Threading, Grinding, Cutting, Engraving, EDM Machining, Riveting.

3. Surface Treatment: Metal Polishing (Metal Mirror Polished, Brushed Metal Finishing), Shot Blasting, Sandblasting, Spray Painting, Powder Coating, Thermal Spraying, Anodizing, Chrome Plating, Nickel Electroplating / Electroless Nickel Plating, Hot-Dip Galvanizing, Copper Plating, Phosphorizing, Electrophoresis and Passivation.

4. Assembly: Stud, Steel Sall & Helicoil Inserts, O-ring, Gasket

5. Packing

6. Testing Report, Quality Control Report

The gravity casting is one type of permanent mold casting, which has advantages of reusable mold, good surface finish, excellent dimensional accuracy and high production rates. The common metal casting material composes aluminum, aluminum alloy, and brass. Material selection is according to technical standards, including ASTM, ANSI, SAE, DIN and BS.

Features

1. Typical parts made by gravity casting includes machine components, various housings, motors, instrument enclosures, etc.

2. The brass gravity cast products are mainly used in fluid control system, such as brass valves, couplings and adapters.

3. Brass cast parts have a wide application in mine industry, oil field, fire fighting field, fluid pressure transmission parts, etc.

4. Besides brass valves, we also produce house decoration parts, brass cast kitchen parts and brass cast furniture parts.

Permanent Mold Casting Processes

Aluminum Gravity Casting

Advantage:

1. Its casting parts have excellent mechanical properties compared with that of die casting parts.

2. Because aluminum gravity cast parts has very lower porosity than aluminum die casting parts.

3. Be generally sound, provided that the casting aluminum alloys used exhibit good fluidity and resistance to hot tearing.

4. Mechanical properties of permanent mold castings can be further improved by heat treatment.

|

|

|

|

|

|

|

|

Brass Gravity Casting

Advantage: Brass gravity cast products have a much superior surface quality than that of brass sand cast products.

|

|

|

|

|

|

|

|

We are a professional supplier of gravity casting in China, offering a high quality affordable permanent mold casting solution. We also provide the following services:

1. Heat Treatment: Hardening, Annealing, Normalizing, Stress Relieving, Softening, and Graphitization.

2. Machining:Turning, Boring, Drilling, Milling, Threading, Grinding, Cutting, Engraving, EDM Machining, Riveting.

3. Surface Treatment: Metal Polishing (Metal Mirror Polished, Brushed Metal Finishing), Shot Blasting, Sandblasting, Spray Painting, Powder Coating, Thermal Spraying, Anodizing, Chrome Plating, Nickel Electroplating / Electroless Nickel Plating, Hot-Dip Galvanizing, Copper Plating, Phosphorizing, Electrophoresis and Passivation.

4. Assembly: Stud, Steel Sall & Helicoil Inserts, O-ring, Gasket

5. Packing

6. Testing Report, Quality Control Report

Inquire Now!

Related Searches: Aluminum Gravity Casting | Gravity Casting Machinery | Gravity Casting Machine | Brass Gravity Casting

English

English