Product List

Metal Casting

- Die Casting

astings with superior mechanical properties....

Tag: Aluminum Alloy Die Casting | Magnesium Die Casting | Die Casting Machinery | Aluminum Die Casting | Bronze Die Casting | Brass Die Casting | Zinc Die Casting

- Gravity Casting

alloy, and brass. Material selection is according to technical standards, including ASTM, ANSI, SAE, DIN and BS....

Tag: Aluminum Gravity Casting | Gravity Casting Machinery | Gravity Casting Machine | Brass Gravity Casting

- Precision Casting

wn as lost wax casting....

Tag: Precision Investment Casting Machine | Precision Low Pressure Casting | Precision Casting Machinery | Precision Gravity Casting | Precision Sand Casting | Precision Die Casting

- Sand Casting

The main sand casting material has iron (grey Iron, ductile Iron, S.G. Iron), bronze, brass, aluminum, zinc, steel, stainless steel, etc. Material selection is according to technical standards, including ASTM, ANSI, SAE, DIN and BS....

Tag: Resin Bonded Sand Casting | Green Sand Casting | Lost Foam Casting | Shell Mold Casting

- Investment Casting

The investment casting is also called lost wax casting. It’s generally used for custom complicated shape casting parts which cannot be reached by die casting or sand casting....

Tag: Investment Casting Machine Machinery | Investment Casting Machine | Lost Wax Casting Machinery | Lost Wax Casting Machine

- Non Ferrous Casting

terial selection is according to technical standards, including ASTM, ANSI, SAE, DIN and BS....

Tag: Non Ferrous Metal Casting Machinery | Non Ferrous Casting Machinery | Non Ferrous Casting Machine | Non Ferrous Mental Casting

We provide a variety of metal casting machine processes, including die casting, gravity casting, precision casting, sand casting, low pressure casting, investment casting and non ferrous casting. The common metal cast materials compose aluminum, aluminum alloy, zinc, brass, bronze, copper alloy, iron, steel, stainless steel, etc. Material selection is according to technical standards, including ASTM, ANSI, SAE, DIN and BS.

Property

1. The actual casting process in metal casting has several forms, the most popular are die casting and gravity casting.

2. The metal parts of die casting have good durable, high dimensional stability and excellent heat resistant when maintaining close tolerances.

3. The gravity casting is one type of permanent mold casting, which has advantages of reusable mold, good surface finish, good dimensional accuracy and high production rates.

4. The process of metal casting involves melting metals at high temperatures and then using molds to shape the metal into new items.

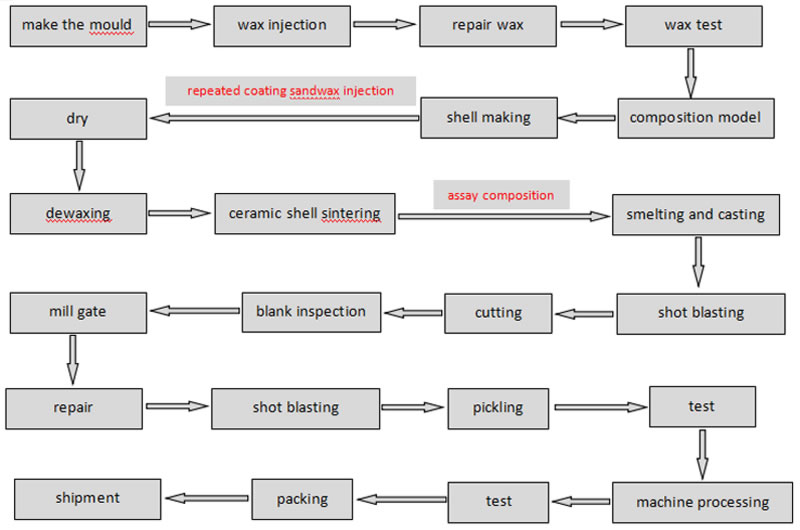

Casting Process Flow Chart

Metal Casting Machine Process

| Die Casting | Gravity Casting | Precision Casting | Sand Casting |

|

|

|

|

| Low Pressure Casting | Investment Casting | Non ferrous Casting |

|

|

|

|

|

Materials of Metal Casting

| 1.Aluminum Casting | 2.Zinc Casting | 3.Brass Casting | 4.Bronze Casting |

|

|

|

|

| 5.Magnesium Casting | 6.Stainless Steel Casting | 7.Carbon Steel Casting | 8.Iron Casting |

|

|

|

|

Metal Casting Machine Post-processing

1. Heat Treatment: Hardening, Annealing, Normalizing, Stress Relieving, Softening, and Graphitization.

2. Machining:Turning, Boring, Drilling, Milling, Threading, Grinding, Cutting, Engraving, EDM Machining, Riveting.

3. Surface Treatment: Metal Polishing (Metal Mirror Polished, Brushed Metal Finishing), Shot Blasting, Sandblasting, Spray Painting, Powder Coating, Thermal Spraying, Anodizing, Chrome Plating, Nickel Electroplating / Electroless Nickel Plating, Hot-Dip Galvanizing, Copper Plating, Phosphorizing, Electrophoresis and Passivation.

4. Assembly: Stud, Steel Sall & Helicoil Inserts, O-ring, Gasket

5. Packing

6. Testing Report, Quality Control Report

English

English