Product List

Low Pressure Casting

Description

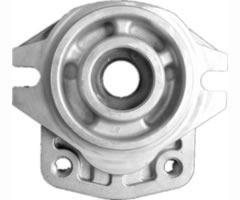

Low pressure casting is a metal casting process that is mostly used in the production of parts made out of aluminum and magnesium alloys. It has advantages of high production yields, excellent cast quality, low per unit costs, high dimensional stability and good shape repeatability.

Application

Low pressure permanent mold casting is especially applied for the production of numerous aluminum automotive parts such as wheels and cylinder heads. It is also used in the chemical and offshore oil industries for the production of security boxes.

Features

1. The molds are usually made of aluminum, and they are designed with cooling channels that can assist in the faster cooling of cast piece, thus improving the productivity.

2. The common low pressure casting material includes aluminium A380, A356, zinc.

3. Material selection is according to technical standards, including ASTM, ANSI, SAE, DIN and BS.

Low Pressure Permanent Mold Casting

We are a professional supplier of low pressure casting in China, offering a high quality affordable low pressure permanent mold casting solution. We also provide the following services:

1. Heat Treatment: Hardening, Annealing, Normalizing, Stress Relieving, Softening, and Graphitization.

2. Machining:Turning, Boring, Drilling, Milling, Threading, Grinding, Cutting, Engraving, EDM Machining, Riveting.

3. Surface Treatment: Metal Polishing (Metal Mirror Polished, Brushed Metal Finishing), Shot Blasting, Sandblasting, Spray Painting, Powder Coating, Thermal Spraying, Anodizing, Chrome Plating, Nickel Electroplating / Electroless Nickel Plating, Hot-Dip Galvanizing, Copper Plating, Phosphorizing, Electrophoresis and Passivation.

4. Assembly: Stud, Steel Sall & Helicoil Inserts, O-ring, Gasket

5. Packing

6. Testing Report, Quality Control Report

Low pressure casting is a metal casting process that is mostly used in the production of parts made out of aluminum and magnesium alloys. It has advantages of high production yields, excellent cast quality, low per unit costs, high dimensional stability and good shape repeatability.

Application

Low pressure permanent mold casting is especially applied for the production of numerous aluminum automotive parts such as wheels and cylinder heads. It is also used in the chemical and offshore oil industries for the production of security boxes.

Features

1. The molds are usually made of aluminum, and they are designed with cooling channels that can assist in the faster cooling of cast piece, thus improving the productivity.

2. The common low pressure casting material includes aluminium A380, A356, zinc.

3. Material selection is according to technical standards, including ASTM, ANSI, SAE, DIN and BS.

Low Pressure Permanent Mold Casting

|

|

|

|

|

|

|

|

We are a professional supplier of low pressure casting in China, offering a high quality affordable low pressure permanent mold casting solution. We also provide the following services:

1. Heat Treatment: Hardening, Annealing, Normalizing, Stress Relieving, Softening, and Graphitization.

2. Machining:Turning, Boring, Drilling, Milling, Threading, Grinding, Cutting, Engraving, EDM Machining, Riveting.

3. Surface Treatment: Metal Polishing (Metal Mirror Polished, Brushed Metal Finishing), Shot Blasting, Sandblasting, Spray Painting, Powder Coating, Thermal Spraying, Anodizing, Chrome Plating, Nickel Electroplating / Electroless Nickel Plating, Hot-Dip Galvanizing, Copper Plating, Phosphorizing, Electrophoresis and Passivation.

4. Assembly: Stud, Steel Sall & Helicoil Inserts, O-ring, Gasket

5. Packing

6. Testing Report, Quality Control Report

Inquire Now!

English

English