Product List

Sheet Metal Fabrication

Description

Sheet metal fabrication is a classification of manufacturing processes that shape a piece of sheet metal into the desired part through material removal and/or material deformation. The commonly sheet metal working materials include aluminum,brass,bronze,copper,stainless steel,steel,tin and zinc.

Features

1. Sheet metal fabrication processes can mostly be placed into two categories - forming and cutting.

2. Forming processes are those in which the applied force causes the material to plastically deform, but not to fail. Such processes are able to bend or stretch the sheet into the desired shape.

Classification of Sheet Metal Working

Sheet Metal Shearing

Press Brake Bending

CNC Metal Punching

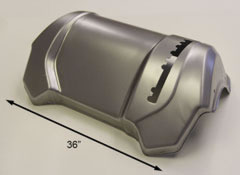

Deep Drawn Stamping

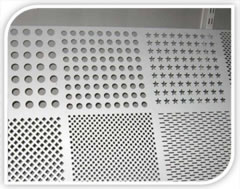

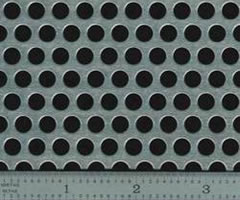

Perforated Metal Sheet

Sheet Metal Riveting

We are a professional supplier of sheet metal fabrication in China, offering a high quality affordable sheet metal working solution. We also provide the following services:

1. Heat Treatment

Hardening, Annealing, Normalizing, Stress Relieving, Softening, and Graphitization

2. Machining

Turning, Boring, Drilling, Milling, Threading, Grinding, Cutting, Engraving, EDM Machining, Riveting

3. Welding

4. Surface Treatment

Metal Polishing (Metal Mirror Polished, Brushed Metal Finishing), Shot Blasting, Sandblasting, Spray Painting, Powder Coating, Thermal Spraying, Anodizing, Chrome Plating, Nickel Electroplating / Electroless Nickel Plating, Hot-Dip Galvanizing, Copper Plating, Phosphorizing, Electrophoresis and Passivation

5. Assembly

Stud, Steel Sall & Helicoil Inserts, O-ring, Gasket

6. Packing

7. Testing Report, Quality Control Report

Sheet metal fabrication is a classification of manufacturing processes that shape a piece of sheet metal into the desired part through material removal and/or material deformation. The commonly sheet metal working materials include aluminum,brass,bronze,copper,stainless steel,steel,tin and zinc.

Features

1. Sheet metal fabrication processes can mostly be placed into two categories - forming and cutting.

2. Forming processes are those in which the applied force causes the material to plastically deform, but not to fail. Such processes are able to bend or stretch the sheet into the desired shape.

Classification of Sheet Metal Working

Sheet Metal Shearing

|

|

|

|

Press Brake Bending

|

|

|

|

CNC Metal Punching

|

|

|

|

Deep Drawn Stamping

|

|

|

|

Perforated Metal Sheet

|

|

|

|

Sheet Metal Riveting

|

|

|

|

We are a professional supplier of sheet metal fabrication in China, offering a high quality affordable sheet metal working solution. We also provide the following services:

1. Heat Treatment

Hardening, Annealing, Normalizing, Stress Relieving, Softening, and Graphitization

2. Machining

Turning, Boring, Drilling, Milling, Threading, Grinding, Cutting, Engraving, EDM Machining, Riveting

3. Welding

4. Surface Treatment

Metal Polishing (Metal Mirror Polished, Brushed Metal Finishing), Shot Blasting, Sandblasting, Spray Painting, Powder Coating, Thermal Spraying, Anodizing, Chrome Plating, Nickel Electroplating / Electroless Nickel Plating, Hot-Dip Galvanizing, Copper Plating, Phosphorizing, Electrophoresis and Passivation

5. Assembly

Stud, Steel Sall & Helicoil Inserts, O-ring, Gasket

6. Packing

7. Testing Report, Quality Control Report

Inquire Now!

Related Searches: Perforated Metal Sheet | Deep Drawn Stamping | Sheet Metal Shearing | CNC Metal Punching | Sheet Metal Riveting

English

English