Product List

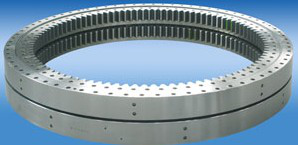

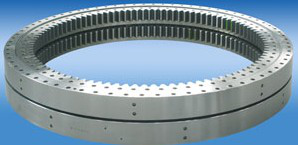

Slewing Ring Bearing

Single Row Four Point Contact Ball Bearing

Description

This series of single-row four point contact ball bearing mainly consists of inside and outside rings. Single-row four point contact ball ring has the features of compact in design, and light in weight. The balls roll on the circular race at four points, so it can bear the axial force, radial force and tipping moment at the same time.

Application:

This slewing ring bearing is suitable for applications in engineering machinery, such as rotary conveyor welding machine, small cranes, small and medium-sized excavators, etc.

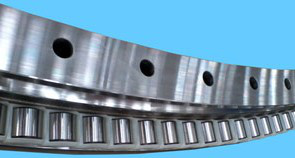

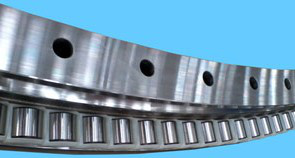

Single Row Cross Roller Slewing Bearing

Description:

Our single row cross roller slewing ring is primarily made up of inside and outside rings. It features compact design, light weight, small assembling clearance and high installation precision. As the rollers are arranged crosswise by 1:1, this turntable bearing is well-suited for high precision mounting, and it’s capable of bearing axial force, radial force and resultant torque simultaneously.

Application:

This series of slewing ring bearing s is extensively applied in lift transport aircraft, construction machinery, and military products.

Double Row Same Ball Slewing Bearing

Description:

This double row same ball slewing bearing is generally made up of inside and outside rings. The up-row and down-row balls enjoy the same diameter. This turntable bearing is suitable for high precision mounting, and it’s capable of bearing axial force, resultant torque and considerably large radial force.

Application:

This series of slewing ring bearing is widely applied by yaw bearing and different types of marine cranes.

Double Row Different Ball Slewing Bearing

Description:

This slewing ring bearing primarily consists of in-up ring, in-down ring and outside ring, so balls and spacers can be directly discharged into the upper and lower raceway. According to stress conditions, bearings are arranged to two rows of balls with different diameters. This turntable bearing is convenient to assembly, and angle of both upper and lower raceways is 90°, so bearings can bear large axial force and resultant torque. Special design is required for the bearing when the radial force is 0.1 times larger than the axial force.

Application:

Large in size and compact in design, this series of slewing ring bearings are particularly suitable for handling equipment that requires at least medium diameter, such as tower crane and mobile crane.

Three Row Roller Slewing Bearing

Description:

This series of slewing ring bearing primarily consists of in-up ring, in-down ring and outside ring. Three rings are separated so the load of each row of roller can be confirmed exactly. This turntable bearing can bear axial force, resultant torque and considerable radial force at the same time. It enjoys compact design and maximum load capacity among these four series.

Application:

This series of slewing ring bearing is ideally suited for heavy machinery, such as bucket wheel excavator, wheeled crane, marine crane, ladle slewing mechanism and large-tonnage mobile crane.

Roller and Ball Combination Slewing Bearing

Description:

This series of turntable bearing is primarily made up of inside and outside rings. The upper row uses rollers and the lower row uses balls. It is suitable for high precision mounting, and it’s capable of bearing axial force, resultant torque and considerably large radial force.

Application:

This slewing ring bearing is perfectly suited for high axial force and continuing working situations. It’s widely applied in ladle slewing mechanism.

Description

This series of single-row four point contact ball bearing mainly consists of inside and outside rings. Single-row four point contact ball ring has the features of compact in design, and light in weight. The balls roll on the circular race at four points, so it can bear the axial force, radial force and tipping moment at the same time.

Application:

This slewing ring bearing is suitable for applications in engineering machinery, such as rotary conveyor welding machine, small cranes, small and medium-sized excavators, etc.

Single Row Cross Roller Slewing Bearing

Description:

Our single row cross roller slewing ring is primarily made up of inside and outside rings. It features compact design, light weight, small assembling clearance and high installation precision. As the rollers are arranged crosswise by 1:1, this turntable bearing is well-suited for high precision mounting, and it’s capable of bearing axial force, radial force and resultant torque simultaneously.

Application:

This series of slewing ring bearing s is extensively applied in lift transport aircraft, construction machinery, and military products.

Double Row Same Ball Slewing Bearing

Description:

This double row same ball slewing bearing is generally made up of inside and outside rings. The up-row and down-row balls enjoy the same diameter. This turntable bearing is suitable for high precision mounting, and it’s capable of bearing axial force, resultant torque and considerably large radial force.

Application:

This series of slewing ring bearing is widely applied by yaw bearing and different types of marine cranes.

Double Row Different Ball Slewing Bearing

Description:

This slewing ring bearing primarily consists of in-up ring, in-down ring and outside ring, so balls and spacers can be directly discharged into the upper and lower raceway. According to stress conditions, bearings are arranged to two rows of balls with different diameters. This turntable bearing is convenient to assembly, and angle of both upper and lower raceways is 90°, so bearings can bear large axial force and resultant torque. Special design is required for the bearing when the radial force is 0.1 times larger than the axial force.

Application:

Large in size and compact in design, this series of slewing ring bearings are particularly suitable for handling equipment that requires at least medium diameter, such as tower crane and mobile crane.

Three Row Roller Slewing Bearing

Description:

This series of slewing ring bearing primarily consists of in-up ring, in-down ring and outside ring. Three rings are separated so the load of each row of roller can be confirmed exactly. This turntable bearing can bear axial force, resultant torque and considerable radial force at the same time. It enjoys compact design and maximum load capacity among these four series.

Application:

This series of slewing ring bearing is ideally suited for heavy machinery, such as bucket wheel excavator, wheeled crane, marine crane, ladle slewing mechanism and large-tonnage mobile crane.

Roller and Ball Combination Slewing Bearing

Description:

This series of turntable bearing is primarily made up of inside and outside rings. The upper row uses rollers and the lower row uses balls. It is suitable for high precision mounting, and it’s capable of bearing axial force, resultant torque and considerably large radial force.

Application:

This slewing ring bearing is perfectly suited for high axial force and continuing working situations. It’s widely applied in ladle slewing mechanism.

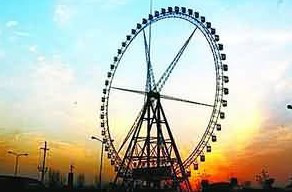

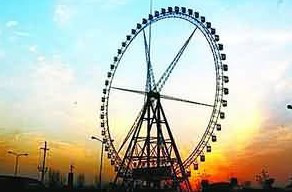

Ferris Wheel Slewing Bearing

Excavator Slewing Ring

Wind Turbine Bearing

Slewing Drive

Ladle Turrent Slewing Bearing

Light Series Slewing Bearing

Ship cranes

Harbor cranes

Offshore cranes

Portal cranes

Crane Slewing Bearing

Tower cranes

Excavator

Mobile crane

Crawler crane

Stacker reclaimer

Construction Machinery Slewing Bearing

Inquire Now!

Related Searches: Injection Molding Machine | Injection Mold Equipment | Injection Molding | Injection Mold Machine | Plastic Injection Mold | Injection Mold

English

English