Product List

Metal Welding

Description

Metal welding (welding fabrication) is a fabrication or sculptural process that joins metals by causing fusion. It is different from low temperature joining technique like brazing and soldering, which do not melt the base metal.

The filler material is often added to the joint to form a pool of molten material (the weld pool), which cools to form a joint that can be as strong as the base material. Pressure may also be used in conjunction with heat, or by itself, to produce a weld.

Advantages

1. We provides a flexible affordable metal welding fabrication solution, includes submerged arc welding (SAW welding), metal inert gas welding (MIG welding), tungsten inert gas welding (TIG welding), spot welding, laser welding and robot welding.

2. we will ensure the following services: suitable materials, affordable cost, reliable quality, test report and stable delivery.

3. The common metal welding materials as follows: steel, stainless steel, aluminum (alloy), brass, bronze, copper alloy, magnesium (alloy), titanium (alloy) and so on.

Classification of Welding Fabrication

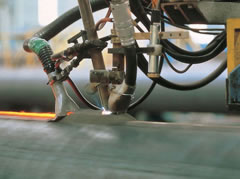

SAW Welding (SAW welding)

Description: The submerged arc welding is a new welding process with high quality, high efficiency and low energy consumption.

Advantage:

1. It has advantages of stable welding quality, high welding productivity, no arc and smoke rarely.

2. Making it become the main pressure vessel and pipe manufacturing

3. Box beam and the fabrication of steel structure welding method

Metal Inert Gas Welding (MIG welding)

Description: It is used for active welding metal and its alloy, such as aluminum, magnesium, magnesium alloy, aluminum alloy, etc.

Advantage:

1. Protect welding arc stability

2. The weld forming uniform and beautiful

3. Improved the welding process and welding efficiency

Tungsten Inert Gas Welding (TIG welding)

Description: TIG welding is widely used in non-ferrous metal aluminum and magnesium alloys, stainless steel, high temperature alloy, titanium and titanium alloy welding, be prone to oxidation, active metal, refractory metal (such as molybdenum, niobium, zirconium, and ordinary carbon steel), low alloy steel and other common materials.

Advantage:

1. It can be successfully welded easy oxidation, nitriding, chemical active strong non-ferrous metals, stainless steel and various alloy.

2. Suitable for welding of ultra-thin sheet, plate material.

Spot Welding

Description: Spot welding is suitable for the manufacture of thin plate can be used, does not require the joint lap airtight, thickness less than 3mm stamping and rolling. The individual points of contact in welding welding joints on the surface. Spot welding requirements to metal has better plasticity.

Advantage: Spot welding is a connection method of high speed and economy.

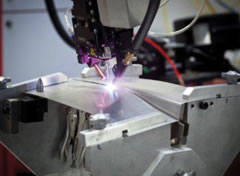

Laser Welding

Description: Laser welding is a high precision welding method used as heat source of high energy density laser beam. Laser welding is one of the important applications of laser material processing technology.

Advantage:

1. The laser beam can be focused in a small area, welding small and similar parts.

2. It can be welded with different physical properties (such as different resistance) of two kinds of metal.

3. It can engage each other all kinds of heterogeneous materials.

4. Automatic high-speed welding, easy to be digital or computer control.

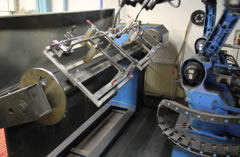

Robot Welding

Description: The welding robot is engaged in welding (including cutting and spraying).

In order to adapt to different purposes, finally a shaft mechanical interface robot, is usually a connection flange. That can be connected with different tools or end effector.

Advantage:

1.Stabilize and improve the welding quality

2.Improve labor productivity

3.Reduce the operating requirements of technical workers

Shorten the product cycle

We are a professional supplier of welding fabrication in China, offering a high quality affordable metal welding solution. We also provide the following services:

1. Cutting (Sheet Metal Shearing, CNC Saw Cut, CNC Torch and Plasma Cut, CNC Laser Cut, CNC Waterjet Cut)

2. Rolling/Bending/Roll Forming (Sheet, Plate, Tube, Pipe, Bar, H/I/L/T Beam, Channel/Angle/Section Steel, Structural Steel)

3. Heat Treatment

Hardening, Annealing, Normalizing, Stress Relieving, Softening, and Graphitization

4. Machining

Turning, Boring, Drilling, Milling, Threading, Grinding, Cutting, Engraving, EDM Machining, Riveting

5. Surface Treatment

Metal Polishing (Metal Mirror Polished, Brushed Metal Finishing), Shot Blasting, Sandblasting, Spray Painting, Powder Coating, Thermal Spraying, Anodizing, Chrome Plating, Nickel Electroplating / Electroless Nickel Plating, Hot-Dip Galvanizing, Copper Plating, Phosphorizing, Electrophoresis and Passivation

6. Assembly

Stud, Steel Sall & Helicoil Inserts, O-ring, Gasket

7. Packing

8. Testing Report, Quality Control Report

Metal welding (welding fabrication) is a fabrication or sculptural process that joins metals by causing fusion. It is different from low temperature joining technique like brazing and soldering, which do not melt the base metal.

The filler material is often added to the joint to form a pool of molten material (the weld pool), which cools to form a joint that can be as strong as the base material. Pressure may also be used in conjunction with heat, or by itself, to produce a weld.

Advantages

1. We provides a flexible affordable metal welding fabrication solution, includes submerged arc welding (SAW welding), metal inert gas welding (MIG welding), tungsten inert gas welding (TIG welding), spot welding, laser welding and robot welding.

2. we will ensure the following services: suitable materials, affordable cost, reliable quality, test report and stable delivery.

3. The common metal welding materials as follows: steel, stainless steel, aluminum (alloy), brass, bronze, copper alloy, magnesium (alloy), titanium (alloy) and so on.

Classification of Welding Fabrication

SAW Welding (SAW welding)

Description: The submerged arc welding is a new welding process with high quality, high efficiency and low energy consumption.

Advantage:

1. It has advantages of stable welding quality, high welding productivity, no arc and smoke rarely.

2. Making it become the main pressure vessel and pipe manufacturing

3. Box beam and the fabrication of steel structure welding method

|

|

|

|

Metal Inert Gas Welding (MIG welding)

Description: It is used for active welding metal and its alloy, such as aluminum, magnesium, magnesium alloy, aluminum alloy, etc.

Advantage:

1. Protect welding arc stability

2. The weld forming uniform and beautiful

3. Improved the welding process and welding efficiency

|

|

|

|

Tungsten Inert Gas Welding (TIG welding)

Description: TIG welding is widely used in non-ferrous metal aluminum and magnesium alloys, stainless steel, high temperature alloy, titanium and titanium alloy welding, be prone to oxidation, active metal, refractory metal (such as molybdenum, niobium, zirconium, and ordinary carbon steel), low alloy steel and other common materials.

Advantage:

1. It can be successfully welded easy oxidation, nitriding, chemical active strong non-ferrous metals, stainless steel and various alloy.

2. Suitable for welding of ultra-thin sheet, plate material.

|

|

|

|

Spot Welding

Description: Spot welding is suitable for the manufacture of thin plate can be used, does not require the joint lap airtight, thickness less than 3mm stamping and rolling. The individual points of contact in welding welding joints on the surface. Spot welding requirements to metal has better plasticity.

Advantage: Spot welding is a connection method of high speed and economy.

|

|

|

|

Laser Welding

Description: Laser welding is a high precision welding method used as heat source of high energy density laser beam. Laser welding is one of the important applications of laser material processing technology.

Advantage:

1. The laser beam can be focused in a small area, welding small and similar parts.

2. It can be welded with different physical properties (such as different resistance) of two kinds of metal.

3. It can engage each other all kinds of heterogeneous materials.

4. Automatic high-speed welding, easy to be digital or computer control.

|

|

|

|

Robot Welding

Description: The welding robot is engaged in welding (including cutting and spraying).

In order to adapt to different purposes, finally a shaft mechanical interface robot, is usually a connection flange. That can be connected with different tools or end effector.

Advantage:

1.Stabilize and improve the welding quality

2.Improve labor productivity

3.Reduce the operating requirements of technical workers

Shorten the product cycle

|

|

|

|

We are a professional supplier of welding fabrication in China, offering a high quality affordable metal welding solution. We also provide the following services:

1. Cutting (Sheet Metal Shearing, CNC Saw Cut, CNC Torch and Plasma Cut, CNC Laser Cut, CNC Waterjet Cut)

2. Rolling/Bending/Roll Forming (Sheet, Plate, Tube, Pipe, Bar, H/I/L/T Beam, Channel/Angle/Section Steel, Structural Steel)

3. Heat Treatment

Hardening, Annealing, Normalizing, Stress Relieving, Softening, and Graphitization

4. Machining

Turning, Boring, Drilling, Milling, Threading, Grinding, Cutting, Engraving, EDM Machining, Riveting

5. Surface Treatment

Metal Polishing (Metal Mirror Polished, Brushed Metal Finishing), Shot Blasting, Sandblasting, Spray Painting, Powder Coating, Thermal Spraying, Anodizing, Chrome Plating, Nickel Electroplating / Electroless Nickel Plating, Hot-Dip Galvanizing, Copper Plating, Phosphorizing, Electrophoresis and Passivation

6. Assembly

Stud, Steel Sall & Helicoil Inserts, O-ring, Gasket

7. Packing

8. Testing Report, Quality Control Report

Inquire Now!

Related Searches: Tungsten Inert Gas Welding | Metal Inert Gas Welding | Submerged Arc Welding | Robot Welding | Laser Welding | Spot Welding

English

English